QBOM – Faster Scheduling as You Draw

QBOM is a newer, faster way to create Bills of Materials, designed to reduce scheduling time.

Instead of waiting until the end of the project, QBOM lets you bubble your drawing as you go, assigning item numbers in real time. Scheduling is handled using the built-in DATAEXTRACTION tool, which is already included in your CAD software.

Because DATAEXTRACTION creates native CAD tables:

- Schedules are easy to format and edit

- Updates are faster when drawings change

- No separate BOM regeneration step is required

The result:

You can get schedules into your drawings earlier, with less rework at the end.

Current Scope:

QBOM currently supports 2D and 3D piping only.

Bills of Materials & Scheduling with Mech-Q

Mech-Q helps you create accurate Bills of Materials by tracking components as you draw.

Every time a fitting or component is placed, Mech-Q records it in the background. When your drawing is complete, you can generate a detailed Bill of Materials (BOM) showing exactly what’s included in the design.

Each Mech-Q module includes its own BOM, allowing you to run estimates, quantities, and reports whenever needed.

Classic Mech-Q BOM Workflow

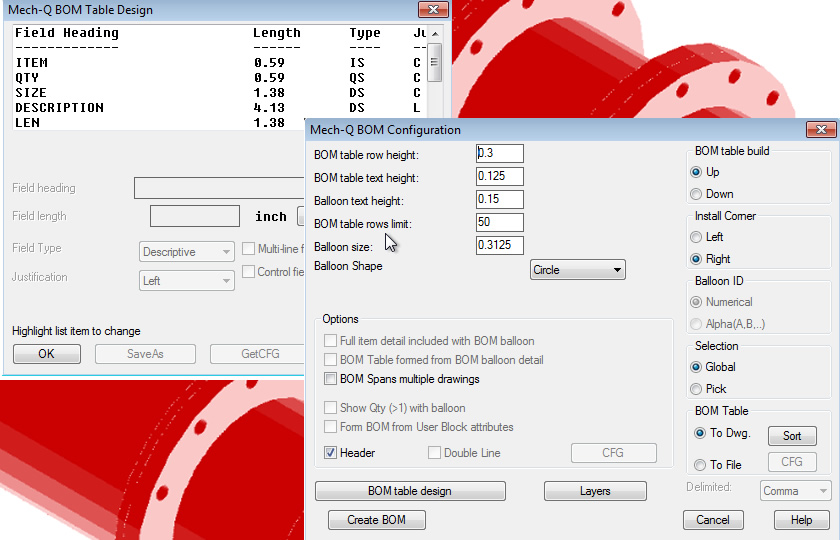

The classic Mech-Q BOM uses a proven, traditional approach to scheduling and works across the full range of Mech-Q tools.

This workflow supports:

- All piping utilities

- Structural Beam utility

- 2D and 3D ducting

With the classic method you can:

- Generate itemized schedules from your drawings

- Bubble or call out items so they correspond to the schedule

- Select only part of a drawing to create spool sheets or partial schedules

This approach is ideal when:

- You want a consistent BOM process across multiple utilities

- You rely heavily on Mech-Q component libraries

- You prefer a structured, end-of-project scheduling step

If Excel is part of your workflow, BOM results can be exported to CSV for further editing, calculations, or estimating.

Editing, Updating, and Exporting Your BOM

Both BOM workflows allow you to:

- Review quantities and part data directly from the drawing

- Update schedules as the design evolves

- Export results to CSV for use in Excel or estimating tools

QBOM adds flexibility by keeping schedules tied directly to drawing data, making late-stage changes easier to manage.

Choose the Workflow That Fits Your Project

Mech-Q gives you options — not limitations.

- If doing 2D or 3D Piping use QBOM when speed and simplicity are the priority

- Use the Classic BOM for full utility coverage and structured scheduling in other modules

Both methods produce accurate, professional schedules. You decide how and when to build them.

Next, explore our different plans

View Next Slide

Or get started now and try Mech-Q now